Description

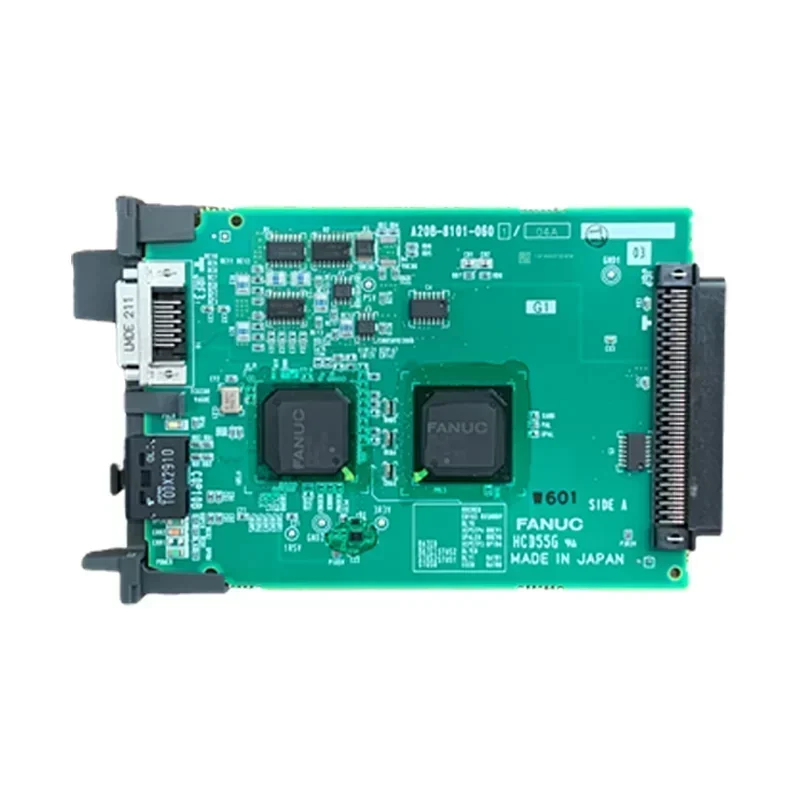

The FANUC A20B-8200-0590 is a critical control printed circuit board (PCB) designed for integration into a specific FANUC Spindle Amplifier Module (SPM), typically within the Alpha i or Beta i series drive systems (A06B-6xxx series SPM units). This board serves as the “brain” of the Spindle Amplifier, housing the digital signal processing (DSP) and communication circuitry necessary to control the machine’s main spindle motor. Its core responsibilities include interpreting high-level spindle speed and orientation commands from the CNC, executing complex motor control algorithms, monitoring current and voltage feedback, and managing alarm conditions to ensure precise, rapid, and stable spindle operation (e.g., maintaining constant surface speed or executing rigid tapping). Failure of this board directly impacts spindle function and often prevents the machine tool from entering automatic mode.

Key Technical Specifications:

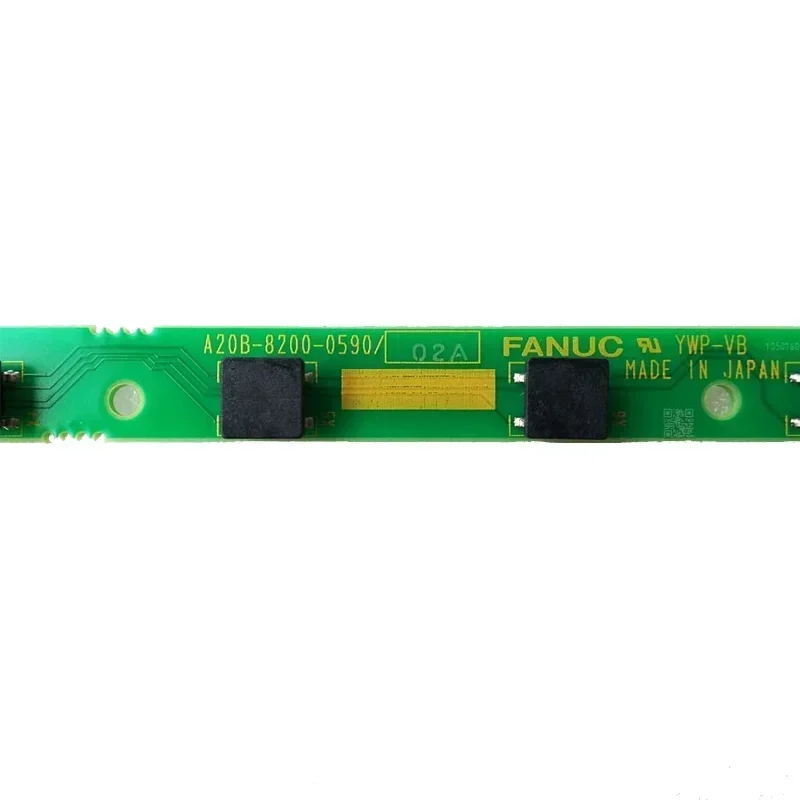

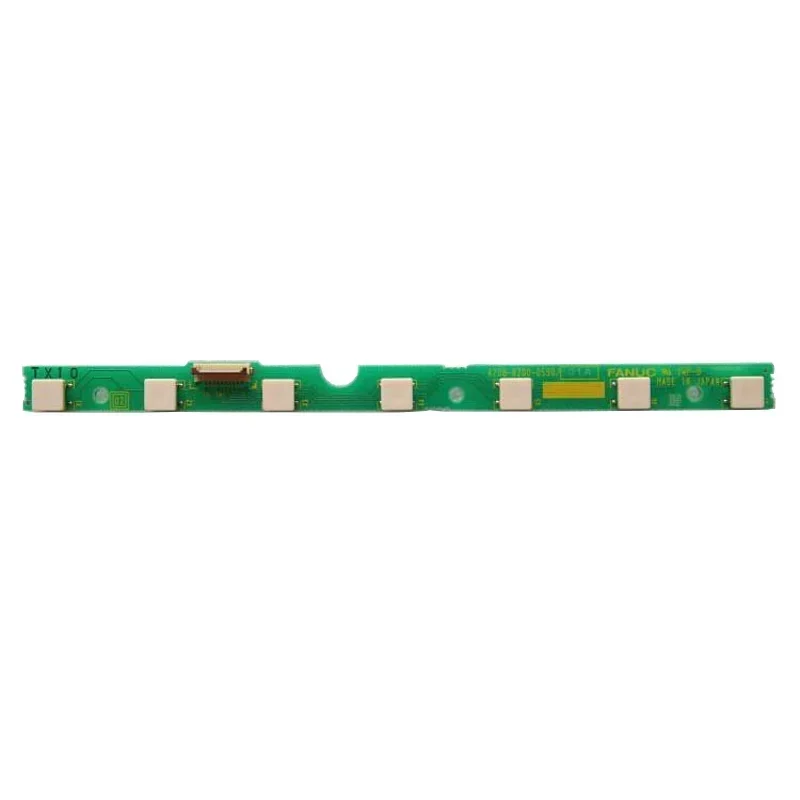

Part Number: A20B-8200-0590

Manufacturer: FANUC

Product Type: Spindle Amplifier Control PCB / Main Board

System Series Compatibility: FANUC Alpha i and Beta i Spindle Amplifiers (SPMs)

Interface: Internal bus communication with power stage (IGBTs) and external connectors for I/O and feedback devices.

Key Function: Digital control, communication, and fault management for the spindle motor.

Failure Symptoms & Diagnosis:

Since this is the control board, failures are often severe and typically result in the Spindle Amplifier displaying critical alarm codes, such as:

– Alarm 750 (Overcurrent): Can be caused by a shorted power stage, but often triggered by faulty gate drive signals from this control PCB.

– Alarm 749 (High Current/Current Feedback Fault): Indicates a problem with the current sensing or the control loop on the board.

– LED Diagnostic Codes: Failure to initialize or continuous blinking/specific LED patterns on the SPM unit, indicating control board corruption or component failure.

RoboSpares MRO Advantage:

Guaranteed Quality: Every control PCB is tested by being installed into a compatible, fully functional Spindle Amplifier and run with a live spindle motor to verify control loop integrity, accurate feedback processing, and reliable communication with a CNC control unit.

Failure Resolution: A tested, cost-effective replacement for modules displaying severe communication faults, control errors, or intermittent spindle operation due to PCB failure.

Rapid Service: Minimize crippling downtime with our extensive component inventory, rapid global shipping, and efficient core Exchange Services.

Warranty: All units are backed by our industry-standard [12/24] Month operational warranty.

Application Notes & Critical Installation Steps:

The A20B-8200-0590 is highly sensitive to static discharge (ESD) and requires careful handling.

1. ESD Protection: Always use a grounding wrist strap and anti-static mats when handling the PCB to prevent irreparable damage.

2. Parameter Backup: Crucially, ensure that all axis and spindle parameters (motor model, scaling, etc.) are correctly backed up and verified, as these may need to be reloaded into the new board upon installation.

3. Connector Seating: Carefully check that all ribbon cables and connectors (especially the power feedback cable connectors) are fully and correctly seated to avoid intermittent faults or short circuits upon power-up.

We mandate that only qualified personnel perform this critical board-level replacement.

Additional information

| Weight | 1 kg |

|---|---|

| Technical Datasheet | A20B-8200-0590.pdf |

Reviews

There are no reviews yet.